TRACS® Model TM500 Ceiling Mount UV-C Air Purification Systems

- Coverage up to 3,600 sq ft every hour or 1,800 sq ft every 30 min

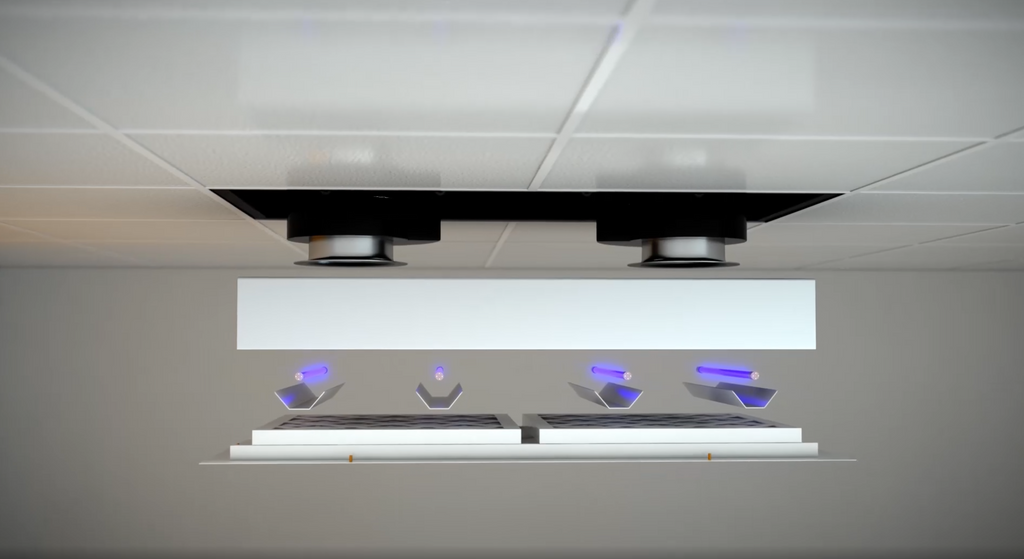

- 3 Stage Air Purification- Pre-Filter, UVGI Technology with Hepa Filtration

- Stage 1- Pleated 1" Antimicrobial Prefilter Merv 10 • Stage 2- 92W of UVC Light at 254 nm

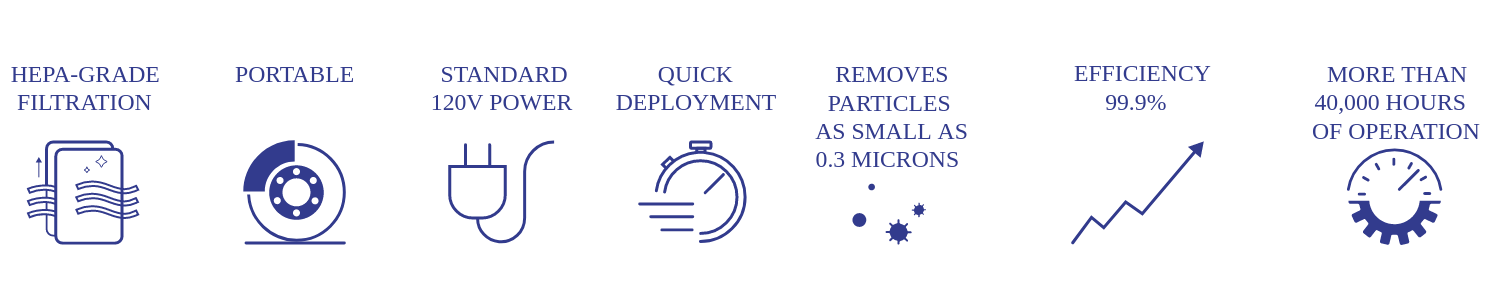

- Stage 3-H13 Certified Hepa Filter is 99.99% Efficiency at .3 Microns, last up to 5 Years

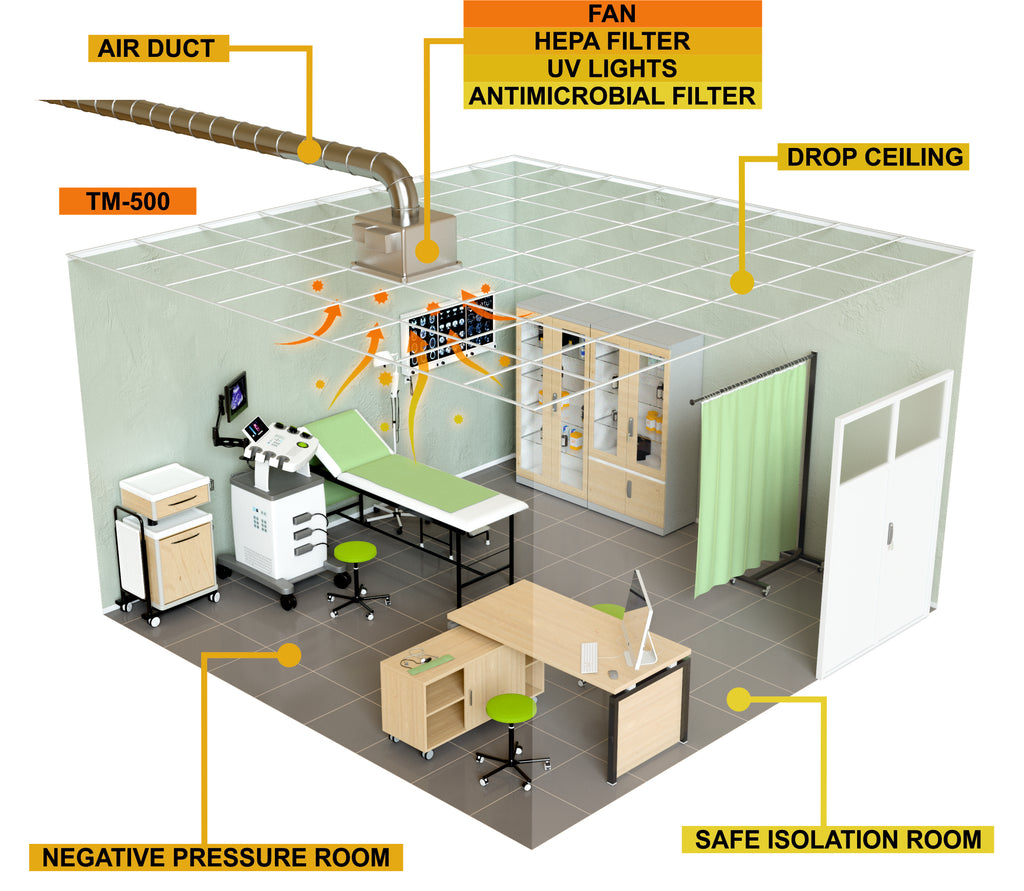

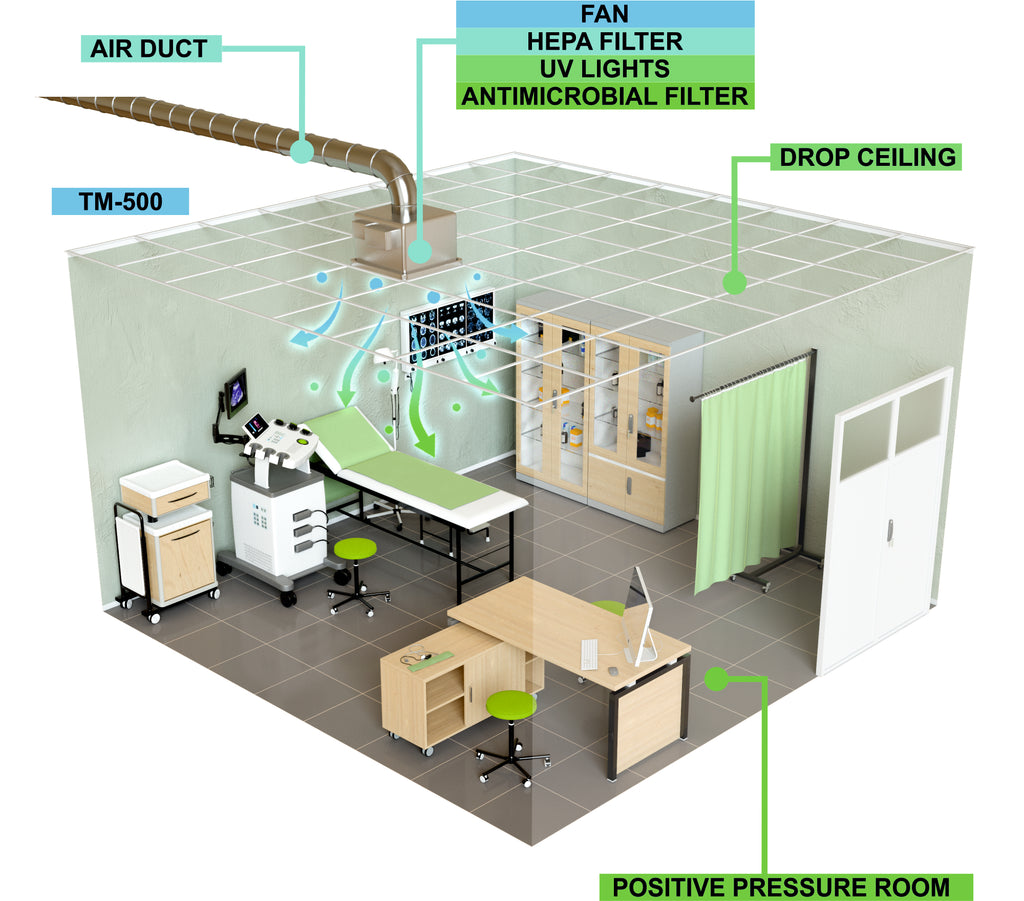

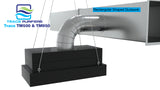

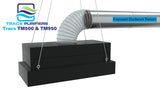

- Dual Mode Air Scrubber and Negative Air Machine

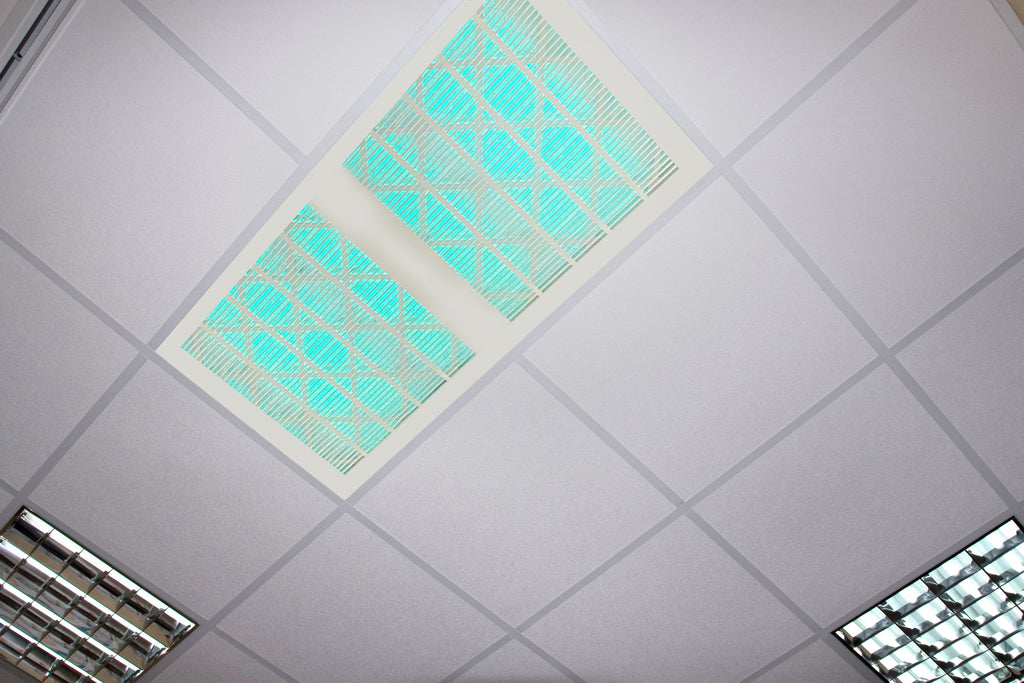

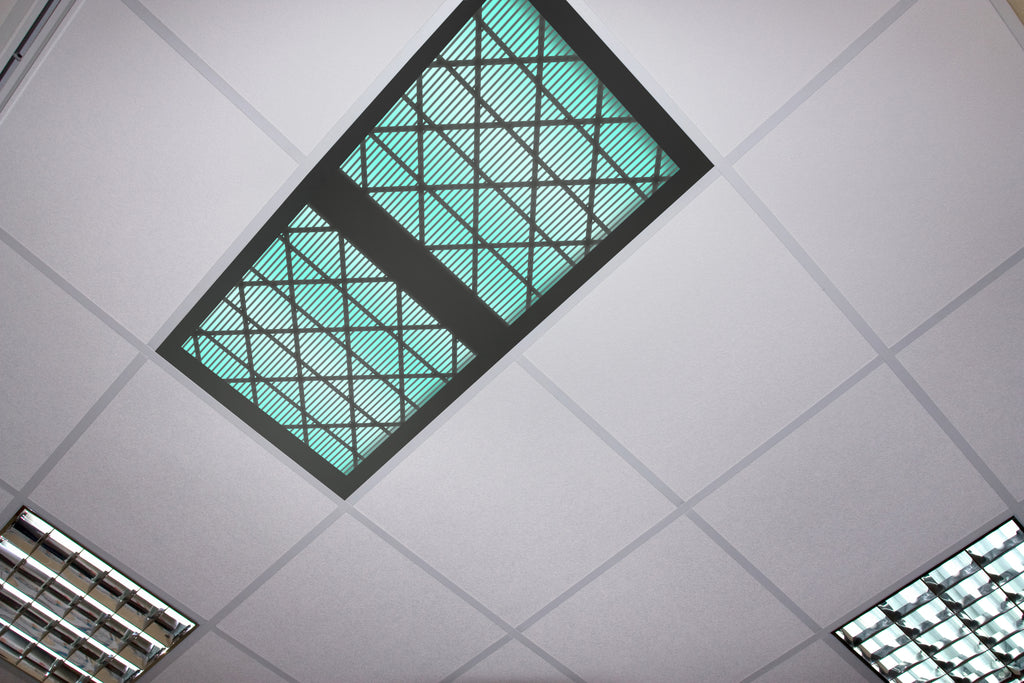

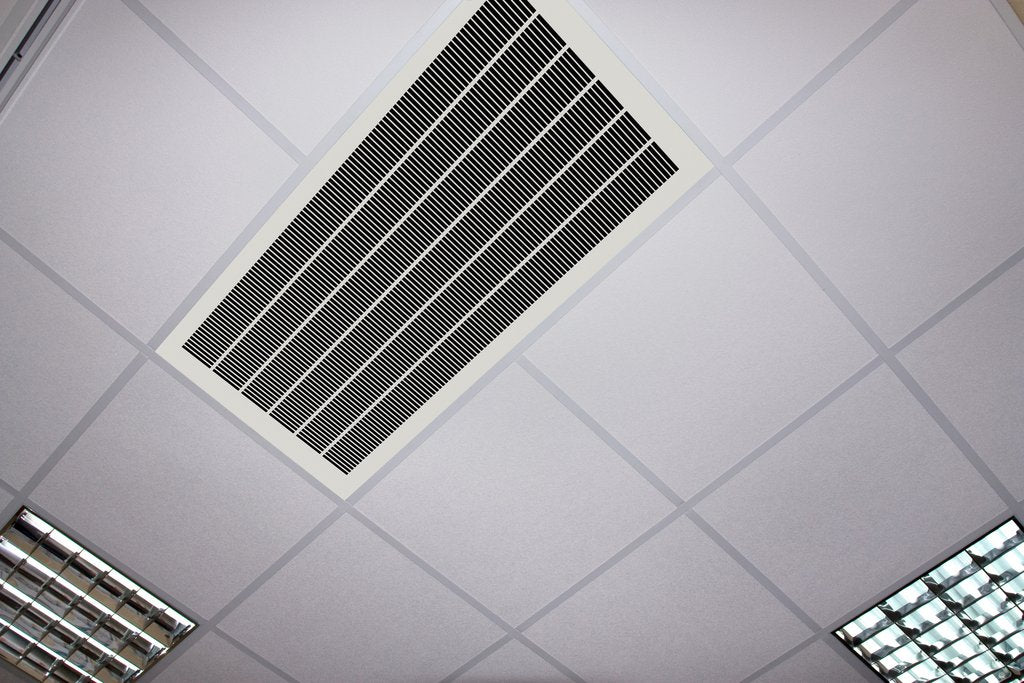

- Mounts in a standard 2’ x 2’ Drop Ceiling

- 5 Year Mechanical Warranty

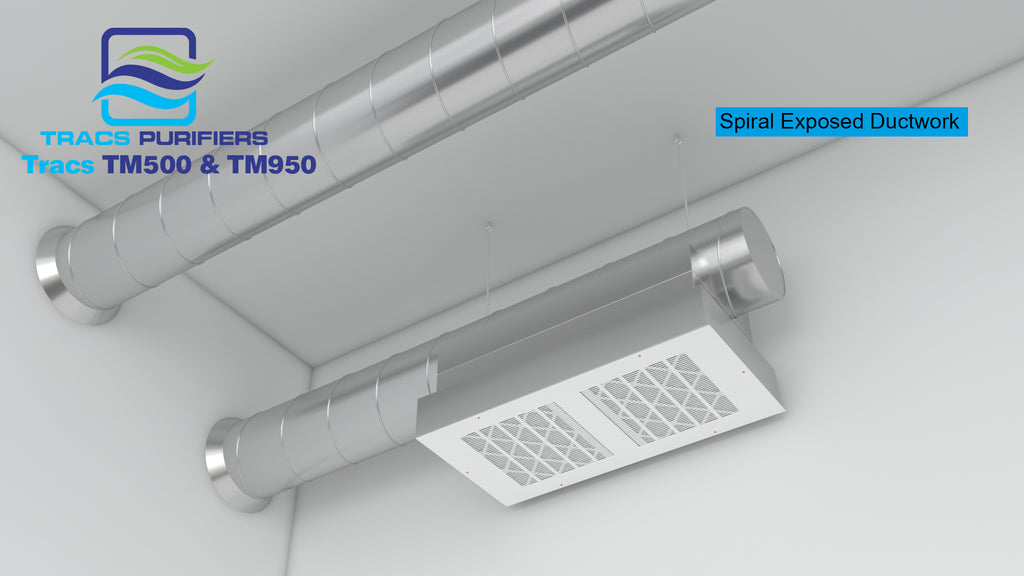

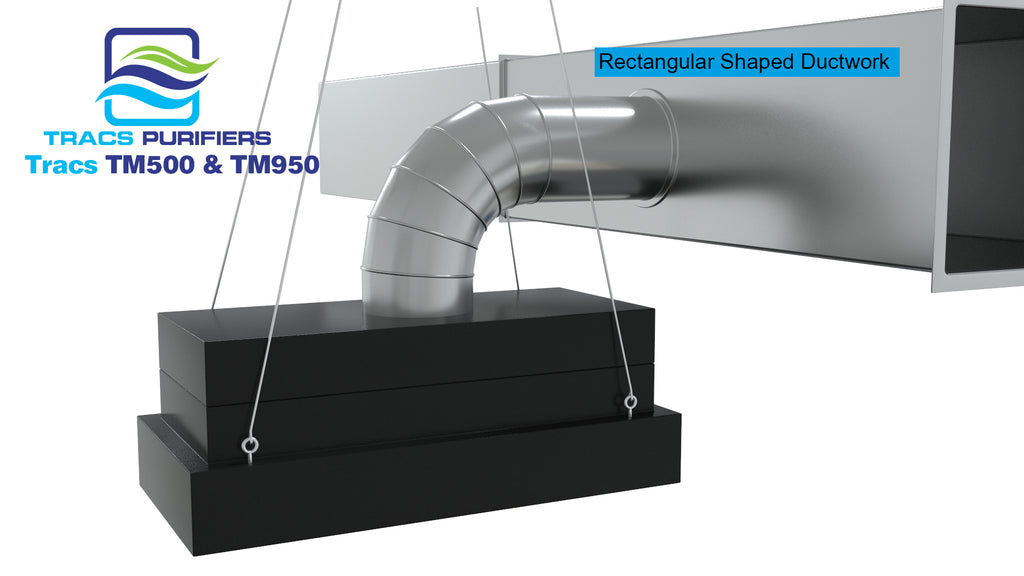

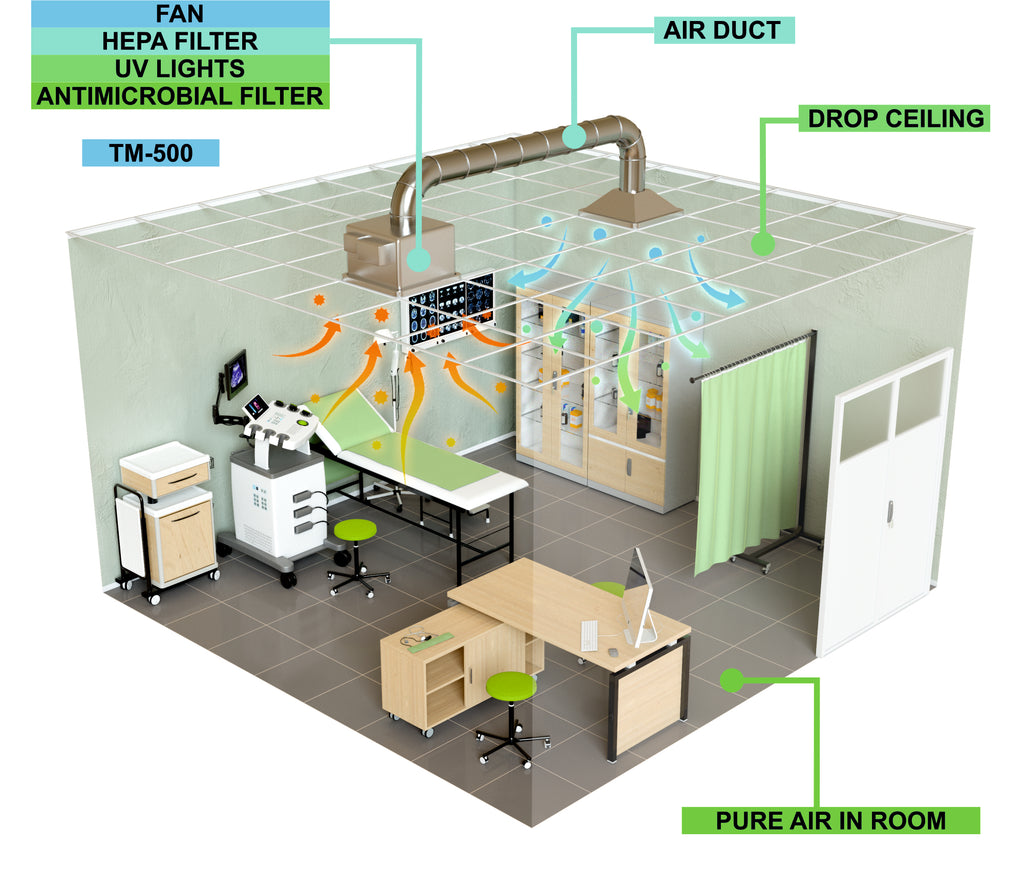

TRACS TM500 Ceiling Mount Air Purification system is a multistage HEPA and UV-C unit that conveniently mount into 2x2 drop ceilings. Features include wall-mounted controls for easy access, antimicrobial pleated prefilter(s), certified HEPA filter, and 22-inch germicidal UV-C lights (254 nm).

This ceiling-mounted air treatment system is used for infection control in medical facilities, laboratories, and compounding rooms in pharmacies, as it is compliant with CDC, JCAHO, or USP <797> requirements. It can be used to clean HVAC supply air, sanitize and recirculate room air, or be vented out to create negative pressure.

Commercial Financing - For orders over $5K - Click Here for 24 Hour Approval.

Benefits

- USA Made

- 5 year Mechanical Warranty

- Free Shipping within the United States

- 30-day Money Back Guarantee

- Affordable Replacement Costs with Auto-Refill Program

Click here to read current report on how UV-C light inactivated airborne human coronaviruses

Viruses may be small enough to slip by a HEPA filter, but most viruses are very susceptible to the effects of UV light. The UV lamps in the TRACS Manufacturing ceiling product line also radiate on the HEPA filter, where the dust, bacteria, and microorganisms are collected.

In HEPA-only systems, mold and microbial growth can occur on the HEPA filter, so HEPA filters must be replaced at least once per year (even if the HEPA filter is not clogged). If they are not replaced, the microorganisms can actually eat through the HEPA media (this is known as bacteria grow-through), and be dispersed throughout the room.

However, in the TM ceiling product line, given the HEPA filter is constantly bathed in UV light, mold and microbial growth cannot occur. As such, the HEPA filters in our systems can last up to three years (depending on particulate load), thereby lowering unit maintenance costs.

We patented the distance between the HEPA filter and UV-light and by having the UV shining on the “dirty” filter, all trapped microorganisms are deactivated, making it safer for the maintenance personnel to change and handle the spent filter.

In summary, UVGI is an effective and valuable secondary or backup technology for high risk infection control applications. Imagine what it could do for your gym, office, or home.

Applications include medical facilities in operating rooms, TB Isolation rooms, Pharmaceutical compounding areas for USP <797> compliance, intensive care units, examination rooms, Emergency Rooms, bronchoscopy/sputum rooms, and waiting areas for cleaning room air, supply air, or creating negative pressure. Also used in laboratories (tissue culture or other high-risk labs), homeless shelters, AIDS clinics, or anywhere there is a high risk of airborne bacteria and disease. Other areas of use are commercial facilities for dust, mold, and microorganism removal, such as computer centers, doctor/dentist offices, daycare centers, morgues, schools and colleges, and general office space.

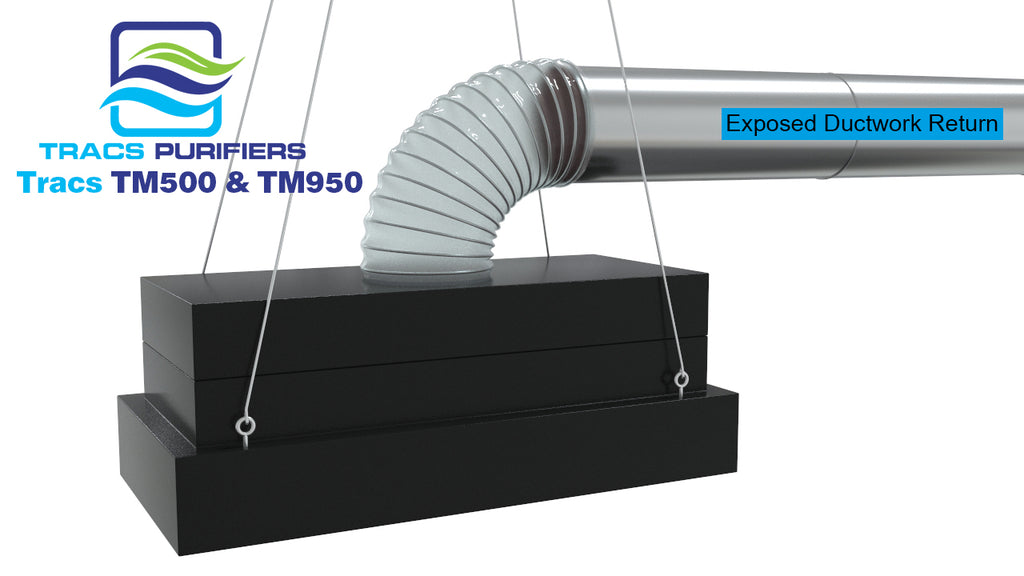

- Used to clean and recirculate room air, disinfect HVAC supply air, or clean exhaust air for the creation of negative pressure.

- Flush Mounted into T-Bar ceiling with room-side access to all replacement parts.

- Certified HEPA filter removes dust and particulate (99.99% efficiency@ .3 mic.)

- UVGI lamps destroy airborne bacteria and viruses and prevent microbial growth on the HEPA filter.

- Negative Pressure Option filters and exhausts room air for the creation of negative pressure.

- Safety interlock switch on all negative pressure UV units shuts power off when intake grille is removed.

- Senior living facilities

- Gyms & fitness centers

- Doctors/Dentist offices

- Educational classrooms

- Office building lobbies

- Medical office waiting areas

- General office space

- Daycare centers

- Operating rooms

- TB Isolation rooms

- Pharmaceutical compounding areas for USP <797> compliance

- Intensive care units

- Examination rooms

- Emergency rooms

- Bronchoscopy/sputum rooms

- Purifying HVAC supply air

- Creating negative pressure

- Laboratories (tissue culture or other high risk labs

- Homeless shelters

- Anywhere there is a high risk of airborne bacteria and disease

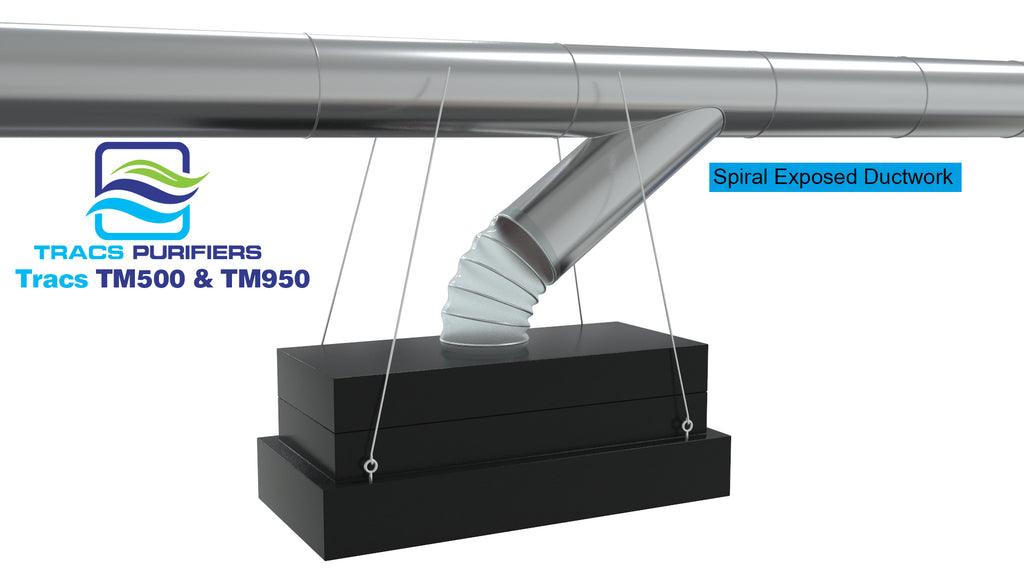

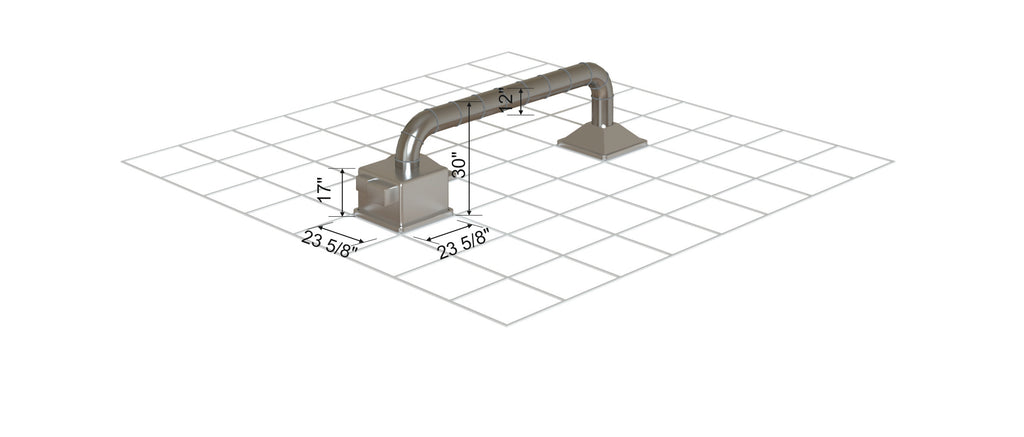

| Dimensions | 23 5/8’’ W x 23 5/8” L x 17” D |

| CFM | 500 CFM |

| Electrical | 120 volt, 60 Hz, single phase TM500: 2.5 amps |

| Room Size | Coverage up to 3600 sq. ft. every hour or 1,800 sq. ft. every 30 min |

| Technology | 3 stage Air Purification- Pre-Filter, Hepa and UVGI Technology. Dual Model Air Scrubber and Negative Air Machine |

| Weight | 49 lbs |

| HEPA Filter | H13 Certified HEPA Filter 99.99% efficiency at .3 Microns |

| dBA | 64 dBA on high |

| Controls | Wall mounted in-room control box equipped with a full variable speed control, LED indicators for each UV lamp, and a UV on/off switch. Mounts in a standard 2’ x 2’ Drop ceiling. |

| UV-C Lamps | Rated for 9000 hours 92W of UVC Light at 254 nm |

| Construction | 20 gauge galvanized steel with powder-coated finish. |

| Warranty | 30-Day Money Back Guarantee, 5-Year Mechanical, Lifetime Frame |

| Maintenance Costs | Pre-Filter: replace every 30-180 days, depending on application, cost is $20 each ($23 with auto refill). Medical Grade HEPA filter: lasts up to 5 years depending on application. UV-C Lamps: change when indicator light goes out, about every 18 months, cost is $39. |

Medical Grade HEPA Filter

For over eighty years High Efficiency Particulate Air Filters (HEPA) filters have been the primary mechanism used for removing airborne pathogens, microorganisms, dust, and particulate from the air at very high efficiencies.

Standard certified HEPA filters are 99.999% efficient at .3 microns and higher, meaning they are individually tested to perform at that efficiency. If a product contains a HEPA filter that is not certified, then it may not perform at HEPA efficiency. This is the case with many commercial units that claim to have “true” HEPA filters.

There are many air purifiers on the market today where the media may be HEPA efficiency but it is not adequately gasketed within the filter frame allowing gases and toxic odors to bypass the filter.

“Certified” HEPA filters are individually DOP tested to ensure efficiency. The HEPA filters used in the TRACS Manufacturing ceiling mounted purifiers are all reverse gel seal filters certified to perform at 99.99% efficiency at .3 microns, and the HEPA filter is securely sealed within the cabinet to prevent air bypass around it.

CarbonWeb pre-filter:

TRACS Manufacturing employs activated CarbonWeb cartridges ($29 refill every 6 months) in the pre-filter process to remove toxic gases and odors too small to be stopped by the HEPA filter. Theoretically, we can remove almost all particulate matter from the air stream. We are now faced with “how should the gases and vapors – the chemical pollution – be removed?” HEPA filtration is effective down to the .3 micron range and will remove some particulates smaller than .3 microns. Gases and vapors are .01 microns and smaller.

Benzene and naphthalene, two compounds that are strongly adsorbed by carbon, are approximately .0006 and .0007 microns respectively. One micron equals 1/25,400 of an inch. Very simply, particulate filters do not, and can not, remove material that is this small and is a gas. If particulate means cannot be used to remove gases, then how can they be removed?

For HVAC applications, where the concentrations are very low and the contaminant loading varies constantly, adsorption has proven to be the most effective and the most economical process.

Adsorption with activated carbon is also the process of choice for applications such as gas masks, space capsules, nuclear submarines and radioactive iodine removal (nuclear plants). Are there other processes to remove gases from an air stream? Certainly, there are other processes. When higher concentrations are present, incineration, chemisorption and solvent recovery [an adsorptive process] all have their places.

- All Children’s Hospital

- Bronx School District

- Savage Arms Inc.

- Stonybrook College

- John’s Hopkins Medical

- Mayo Clinic

- Foxwoods Casino

- Mohegan Sun Casino

- Hartford Hospital

- St. Francis Hospital

- Cleveland Clinic

- NASA Offices - Cleveland

- NASA Offices - Cape Canaveral

- NASA Offices - Houston

- General Services Administration

- Metropolitan Museum of Art - NY

- Michigan State PD

- Endita Medical Center

- El Paso County Health Dept.

- Valverde Correctional Facility

- Missouri Department of Health - Every hospital in Missouri has a medical unit

- Hawaii Dept. of Corporate Council

- Kapiolani Medical Center

- Dept. Rehab Services - OK Grainger

- Church of Scientology

- Crescent City Police Department

- Kyle Police Department

- City of Kansas City

- Green County Sheriffs Office

- Surfside Beach Police Department

- Big River Ambulance District

- Dept. of State Health Services - TX

- Colleyville Police Department

- North Haven Police Department

- City of Deltona

- City of Seguin

- Immunovative Clinical Research

- David Pena Best Research Solutions

- US EPA - Washington DC

- Humane Association of Warren County

- US Air Force

- City of Bunnell Police Department

- Ritz Carlton Hotels

- Good Samaritan Clinic

- Nat. Institute of Health -

- Bethesda Kyle Police Department

- Ronald McDonald House

- Life Vessel Santa Barbara

- Shiepis Clinic

- United States Army

- Dow Chemical

- Northern California Power Agency

- San Leandro Hospital

- Columbia University

- Palm Beach Housing Authority

- NW Community Mental Health